Development of high-precision, high-efficiency machining tools

Department of Mechanical Engineering

MATSUZAKI Kenichiro

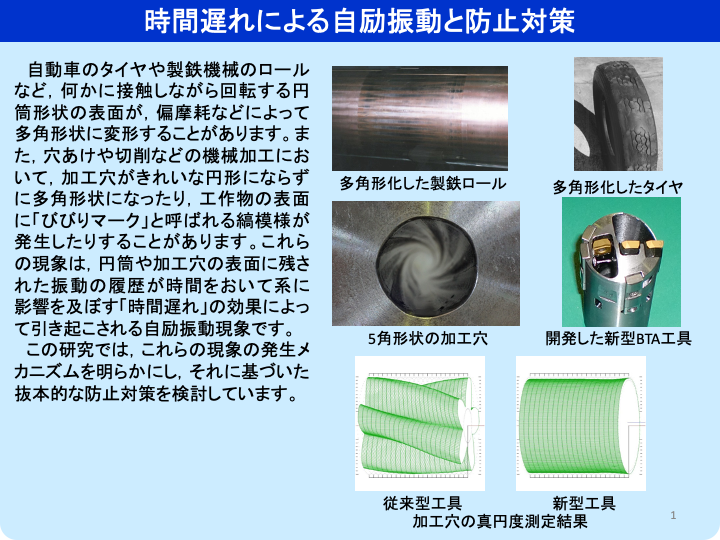

Background and objectives of activities

As one of the metalworking processes in manufacturing, the cutting process is the process of cutting a material with a tool. During cutting, a large force is applied to the tool and the material, causing vibration. Vibration during machining can reduce machining accuracy and damage tools, so measures are needed to prevent and suppress vibration during machining.

Summary of Activities

This research clarifies the mechanism of vibration generation in hole drilling using drills and straight and curved line machining using end mills, and examines the development of tools and machining conditions to reduce vibration phenomena.

Expected Benefits

Expected to improve machine quality and production efficiency by increasing machining accuracy and efficiency.